65Mn Spring Steel

We are a GB 65Mn steel stockholders and China suppliers. And fushun Special Steel supply in GB 65Mn Spring Steel round bar, flat bar, rod bar, wire and plate supply.

Moreover, GB 65Mn Steel is a high quality Alloy Spring Steel, and it belong to the high quality high carbon alloy Spring Steel.Its Quenched & Tempered Hardness is 28-34 HRC. 65Mn steel under Annealing delivery hardness less than 250HB.

65Mn steel is a Chinese GB standard spring steel grade, Manganese (Mn) improves hardenability, so the strength, hardness, elasticity and hardenability are higher than that of 65# steel, but it has overheat sensitivity and temper brittleness. Water quenching tends to form cracks. The annealed state has good machinability, low cold deformation plasticity, and poor weldability.

65Mn high carbon steel is mainly used in the manufacture of various small-section flat springs, round springs, clockwork, etc. It can also be used to manufacture spring rings, valve springs, shock absorbers, clutch reeds and brake springs.

65Mn Datasheet

Below is material AISI 65Mn spring steel datasheet including chemical composition, properties and heat treatment, etc.

Chemical Composition

The table below lists 65Mn high carbon steel chemical composition based on heat analysis.

| Chemical Composition, % | |||||||||

| Standard | Grade | C | Si | Mn | P, ≤ | S, ≤ | Cr, ≤ | Ni, ≤ | Cu, ≤ |

| GB/T 1222 | 65Mn | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | 0.030 | 0.030 | 0.25 | 0.35 | 0.25 |

65Mn Material Properties

Density: 7.85 g/cm3

| Mechanical Properties | ||||||

| Standard | Grade | Tensile Strength, MPa, ≥ | Yield Strength, MPa, ≥ | Elongation, %, ≥ | Reduction in Area, %, ≥ | Brinell Hardness, HBW, ≤ |

| GB/T 1222 | 65Mn | 980 | 785 | 8.0 | 30 | 302 |

Notes: Bars with a diameter and side length of not more than 80 mm and flat steels with a thickness of not more than 40 mm.

| Tensile strength | Conditions to yield strength | Elongation | Reduction of area | Hardness (Hot Rolled) | Hardness (Cold Drawn) |

| σb (MPa):≥980 | σ0.2 (MPa):≥785 | δ 5 (%):≥8 | ψ (%):≥30 | ≤302HB; |

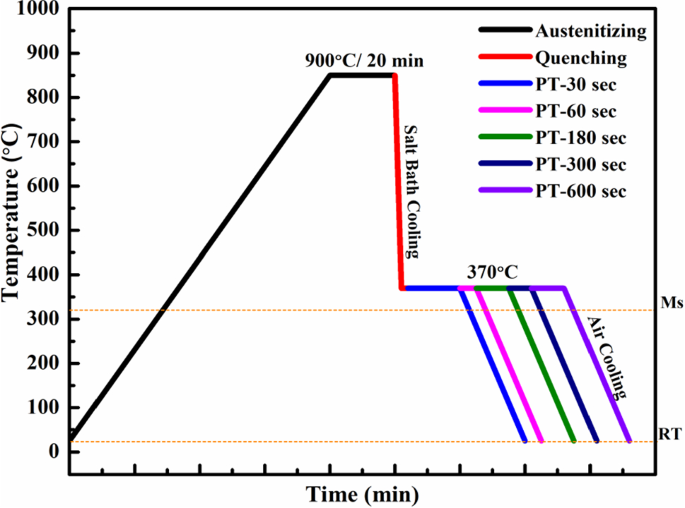

Heat Treatment Specification

| Heat Treatment | ||||

| Standard | Grade | Quenching temperature, °C | Quenching medium | Tempering temperature, °C |

| GB/T 1222 | 65Mn | 830 ± 20 | Oil | 540 ± 20 |

Annealing process: Annealing temperature (860 ± 10) °C, heat preservation for 45-60min, furnace cooling to (750 ± 10) °C, heat preservation for 3-3.5h, and furnace cooling to 650-660 °C, then cooling out of the furnace or slow cooling in a heat preservation pit.

Heat treatment Related

Annealing of 65Mn Spring Steel

At first Slowly heated to 730 ℃ and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace. Then 65Mn tool steel will get MAX 250 HB (Brinell hardness).

Hardening of 65Mn Spring Steel

At the beginning, 65Mn steels should be heated uniformly to 830-860°C (1526-1580°F) until completely heated through. After about 30 min per 25 mm of ruling section is to be provided and then the steels should be immediately quenched in oil. Tempering of 65Mn Spring Steel

Tempering of 65Mn steels is performed at 540°C, Soak well at the selected temperature and soak for at least one hour per 25mm of total thickness. Hardness values at different temperatures after tempering

Applications

65Mn steel, after heat treatment and cold drawing hardening, high strength, it has a certain toughness and plasticity; In the same surface hardening case, completely and the fatigue limit and alloy spring. But hardenability poor, mainly for the smaller size of the spring, such as regulating speed regulating spring, spring load, general machinery in the round, square spiral spring or pull wire for small mechanical spring.

65Mn Spring Steel Equivalent

65Mn steel is considered to be equivalent to AISI SAE 1065, and some people also compare 65Mn with AISI/SAE 1075, 1095, 5160; JIS SK5 (SK85) and Chinese 8Cr13Mov, so the table below lists the difference of chemical composition for your reference.

65Mn vs 1065, 1075, 1095, 5160, SK5 and 8Cr13Mov in chemical composition

| Chemical Composition % | ||||||||||

| Grade | C | Si | Mn | P (≤) | S (≤) | Cr | Ni (≤) | Cu (≤) | Mo | V |

| 65Mn | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | 0.030 | 0.030 | ≤ 0.25 | 0.35 | 0.25 | – | – |

| 1065 | 0.60-0.70 | 0.60-0.90 | 0.040 | 0.050 | – | – | (0.20) | – | – | |

| 1075 | 0.70-0.80 | 0.40-0.70 | 0.040 | 0.050 | – | – | (0.20) | – | – | |

| 1095 | 0.90-1.03 | 0.30-0.50 | 0.040 | 0.050 | – | – | (0.20) | – | – | |

| 5160 | 0.56-0.61 | 0.15-0.35 | 0.75-1.00 | 0.035 | 0.040 | 0.70-0.90 | – | (0.30) | – | – |

| SK5 | 0.80-0.90 | 0.10-0.35 | 0.10-0.50 | 0.030 | 0.030 | 0.30 | 0.25 | 0.25 | – | – |

| 8Cr13Mov | 0.70-0.80 | 1.00 | 1.00 | 0.040 | 0.030 | 13.00-14.50 | 0.60 | 0.10-0.30 | 0.10-0.25 | |

What is 65 MN Steel?

65 Mn spring Steel is a low alloy carbon steel, it’s known for making knives and machete knives, small-section flat springs, round springs, clockwork. Being carbon steel makes it hard steel but comes with lower corrosion resistance level.

How hard is 65 MN steel? – 65 MN steel hardness

With a hardening capability of 28-34 HRC, 65 Mn is hard steel.

65 MN steel properties

According to the chemical composition and the HRC of the steel, the 65 MN Steel has the following features:

65 MN Edge Retention: With a maximum hardness of 34HRC, the steel can offer a good hardness, therefore good edge retention.

65 MN Corrosion Resistance: Not very great for corrosion resistance with only 0.2% of chromium.

65 MN Wear Resistance: With 0.65% carbon, this steel offers a good wear resistance.

65 MN Sharpness: The rule says the harder the steel, the harder to sharpen it, the 65MN is a hard steel that wouldn’t be so easy to sharp.

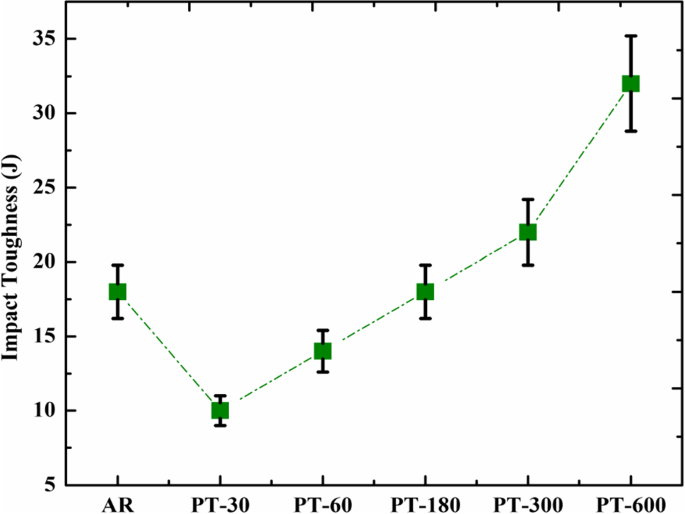

65 MN Toughness: Great toughness thanks to the mixture of Carbon, Chromium, and Manganese.

65Mn steel overviews

| Size | Round | Dia 6-1200mm |

| Plate/Flat/Block | Thickness 6mm-500mm |

|

| Width 20mm-1000mm |

||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Payment terms | T/T;L/C;/Money gram/ Paypal | |

| Trade terms | FOB; CIF; C&F; etc.. | |

| Delivery time | 30-45 days | |

| Application | 65Mn high carbon steel is mainly used in the manufacture of various small-section flat springs, round springs, clockwork, etc. It can also be used to manufacture spring rings, valve springs, shock absorbers, clutch reeds and brake springs, regulating speed regulating spring, spring load, general machinery in the round, square spiral spring or pull wire for small mechanical spring. | |

For hot rolled plate, usually the delivery condition is hot rolled, annealed/QT, black surface.

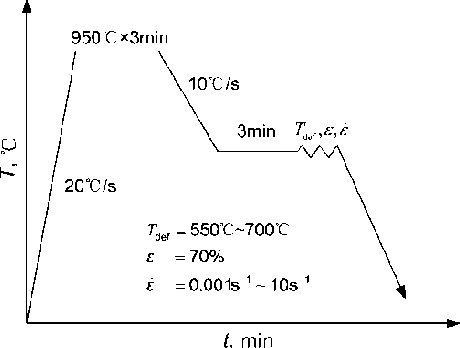

The mechanical properties of the heat treated 65Mn steel that produced by CSP (Compact Strip Production) and conventional continuous casting process were investigated. Measured results showed that 65Mn steel produced by CSP exhibits higher hardness than that produced by conventional continuous casting process. The better mechanical property was attributed to fine-grained microstructures in the as-rolled CSP strips.