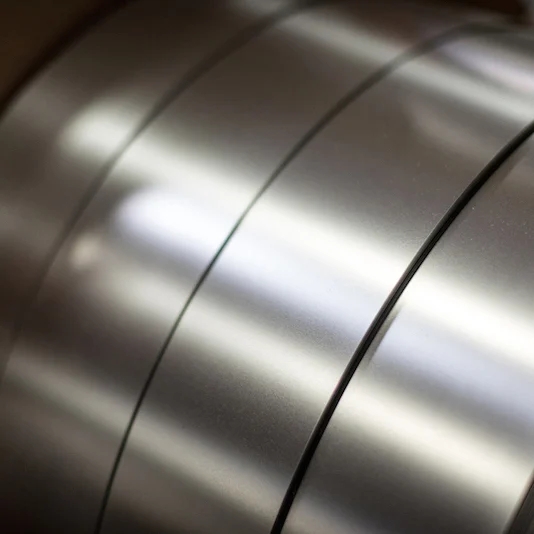

Ultra High Purity Nickel Strip

Our pure nickel strip offerings are meticulously engineered to achieve an exceptional purity level of 99.98%, specifically tailored for critical battery connector applications. We utilize an advanced wrought powder metallurgy process, setting our materials apart from standard wrought nickel battery strips. The key advantages are as follows:

– 15-20% superior conductivity compared to conventional cast nickel strips

– Stringent control over chemical composition

– Available in both standard and customizable sizes & tempers

– Short lead times and accommodating minimum order sizes

– Exceptional surface finish

High-Purity Nickel Strip Grades

We provide three distinct high-purity nickel alloy strip grades primarily designed for battery connector applications:

Nickel 270 – UNS N02270 (899A) – WNR 2.4050

Nickel 270 strip (899A) is our highest purity material with superior conductivity to cast products and offers the most flexibility in design for cost savings, weight reduction, or increased power.

Nickel 201/200 – UNS N02201, N02200 (899L) – WNR 2.4068

Nickel 201/200 strip (899L) is our premier battery grade that offers improved conductivity over Nickel 200 and 201 while maintaining closer mechanical properties to the lower conductivity materials.

Nickel 201/200 – UNS N02201, N02200 (899M) – WNR 2.4068

Nickel 201/200 strip (899M) is produced as a replacement for Nickel 200 and 201 with similar mechanical properties and without the higher conductivities attributed to higher purity grades such as 899L and 899A.

Nickel Strip Dimensions

Our specialization lies in rolling nickel strip and nickel alloy materials to slender thicknesses, available in standard and bespoke sizes:

– Thickness: Ranging over 0.0001” (0.000254mm)

– Width: Extending under 15” (380mm)

| Nickel Strip Grades | Industry Equivalents | Nickel Strip Grades | Industry Equivalents |

| High Purity | Dispersed Phase | ||

| Nickel 270 (899A) | UNS N02270 | Nickel 205 (899D) | UNS N02205 |

| Nickel 201/200 (899L) | UNS N02201 / UNS N02200 | Nickel 205 (899E) | UNS N02233 |

| Nickel 201/200 (899M) | UNS N02201 / UNS N02200 | Nickel 225 (899G) | UNS N02233 |

| Nickel 201 | Ni99 | N02201

ASTM B162 |

DIN 2.4068 |

| Nickel 200 | Ni99.2 | N02200 | DIN 2.4066 |

| Nickel 206 | Ni99.6 | – | DIN 2.4060 |

| Nickel U | NiCoMnC | ||

| Nickel 206T | Ni99 | ||

| Nickel 206C | Ni99 | ||

| Nickel 206A | Ni99.6 | ||

| Nickel 206 BC | NiMnSiC | ||

| Description | |||

| High Purity Nickel strip made by wrought Powder Metallurgy technology. Our process produces high conductivity materials (99.98% Nickel Strip) used in collectors and connector tab for many battery chemistries.. | |||

| Advantages | |||

| l Outstanding Electrical Conductivity

l Pure nickel strip with the lowest electrical resistivity on the market l Uniformity, microcleanliness, and precise composition control for improved weldability l Minimal surface oxide content to minimize die wear and ensure exceptional solderability l Exceptional malleability l Resistance to tarnish and chemical reactivity under standard atmospheric conditions l Ease of plating l Moderate resistance to acidic environments l Superb resistance to caustic solutions |

|||

99.98% Pure Nickel Strip for 15-20% Enhanced Conductivity

We employ a low-temperature roll compaction process to minimize the formation of impurities within our nickel strip. This heightened purity diminishes impedance and elevates conductivity by 15-20% when compared to competing materials, enabling superior power transmission and enhanced performance in battery applications. Our wrought powder metallurgy process also offers precise control over low-level alloying additions, distinguishing it from standard cast products that often contain non-metallic inclusions as a result of hot rolling slabs in unprotected environments.

Battery Applications

Our nickel strip products find their primary utility in connecting multiple NiMh, NiCd, or Li-Ion batteries within battery packs. Additionally, they serve various other battery applications, including battery tabs, cathodes, switchgear connections, and nickel mesh used in battery catalysts.